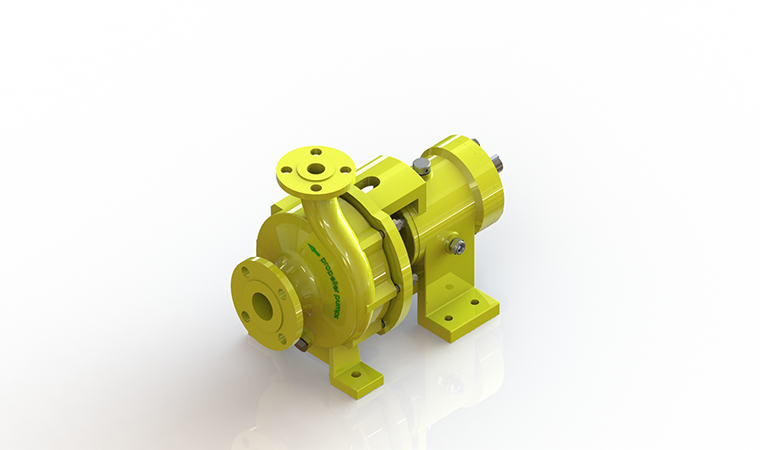

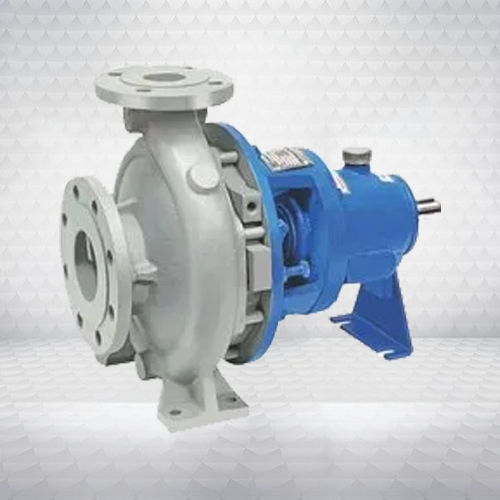

Chemical Process Pump

Chemical Process Pump

A chemical process pump is a type of pump that is specifically designed for handling and transferring corrosive, abrasive, and hazardous fluids in chemical processing applications. Chemical process pumps are essential in industries such as petrochemicals, oil and gas, pharmaceuticals, food and beverage, and water treatment.

Chemical process pumps are designed with materials that are resistant to corrosion and abrasion. These materials can include various types of plastics, ceramics, metals such as stainless steel, and special coatings. The pumps are also designed with tight tolerances to ensure that they can handle fluids that may contain solid particles, such as slurries.