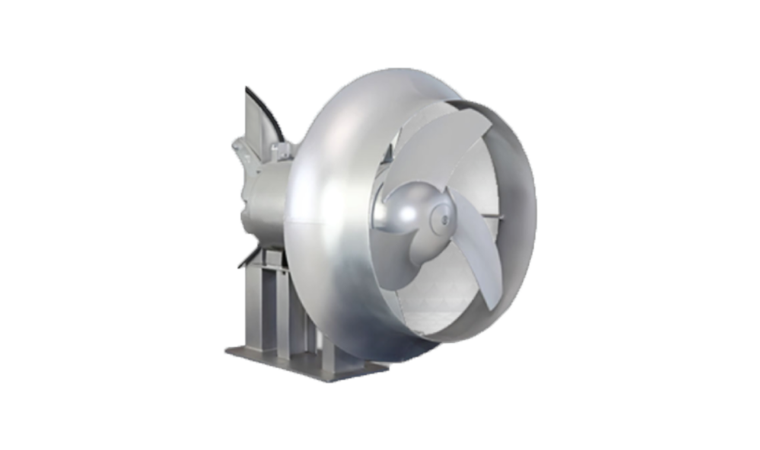

Submersible Agitator And Mixure

Submersible Agitator And Mixure

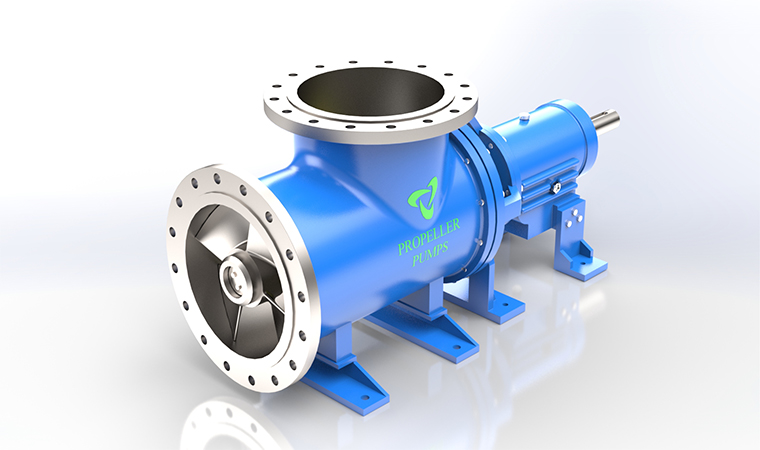

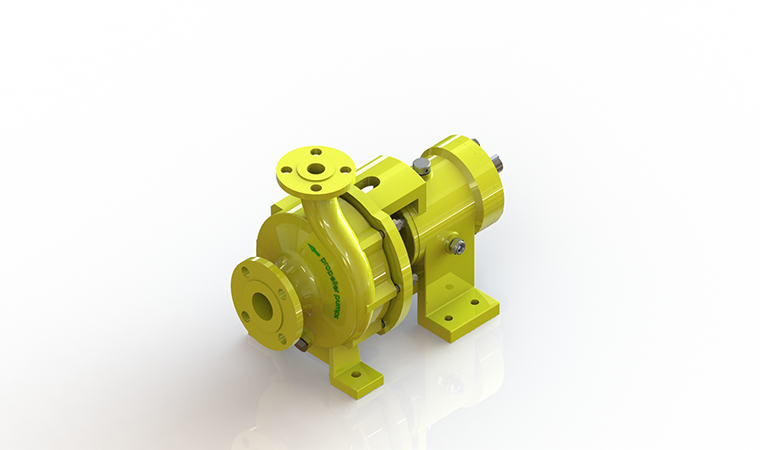

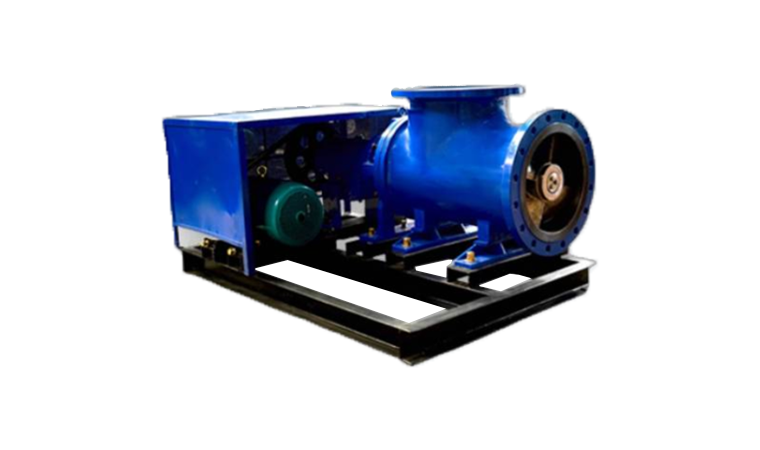

Submersible agitator mixers from Propeller Pumps can be used in a variety of industrial and sewage treatment facilities. In industries and municipal treatment facilities, they offer the appropriate solution to match mixing tasks for agitation, blending, mixing, dissolving, and suspension of solids.