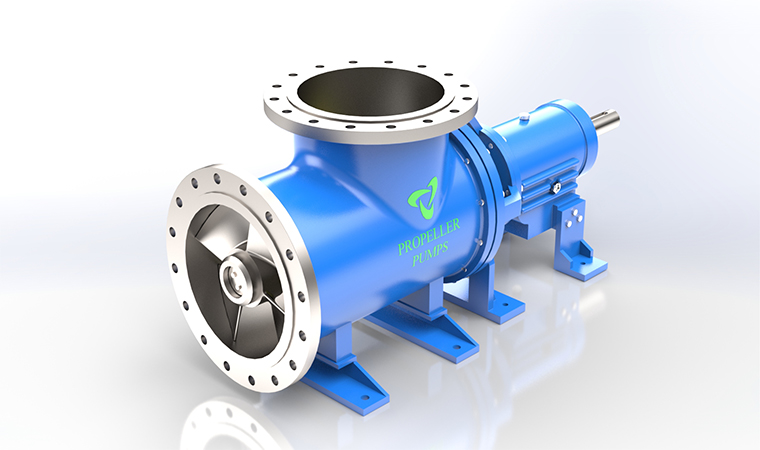

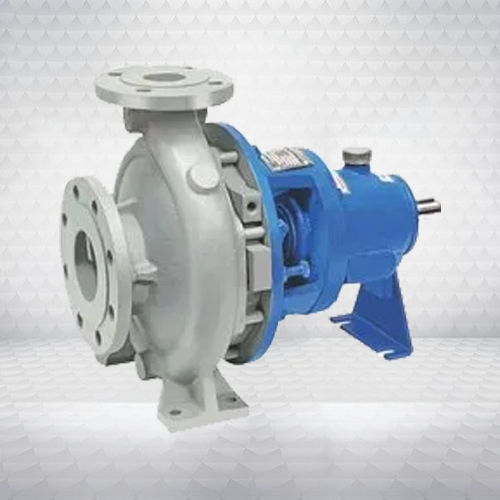

Horizontal Axial Flow Pump

Horizontal Axial Flow Pump

A horizontal axial flow pump is a type of axial flow pump in which the axis of rotation is oriented horizontally. This design is commonly used in applications that require a high flow rate and a low head, such as irrigation, flood control, and drainage.

In a horizontal axial flow pump, the impeller rotates within a volute casing, and the fluid is drawn into the pump through an inlet and exits the pump through an outlet. The design of the impeller and volute casing helps to minimize turbulence and increase the efficiency of the pump.